industrial screens

Conveyall Industrial Supply, Inc. offers a wide range of synthetic screen media. We can utilize urethane, rubber and other products to solve your screening issues such as blinding, pegging, wear and noise. Contact us today—give us your heartburn application and we will guarantee results in writing.

Wire cloth screens can be provided in a variety of configurations and can be supplied with a variety of different metals. Punch plates and woven wire can be utilized to give your operation a large return on investment.

We can show you money-saving ideas to pad your bottom line. Our experts can perform a complete screen audit to improve your screen wear life and increase your ROI. We can complete a variety of improvements on applications—without changing your screen set up. Call us today put our team to work for your operation and start adding to your bottom line.

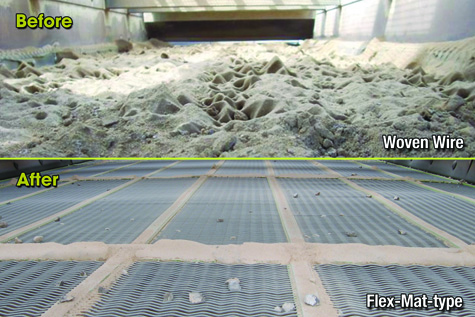

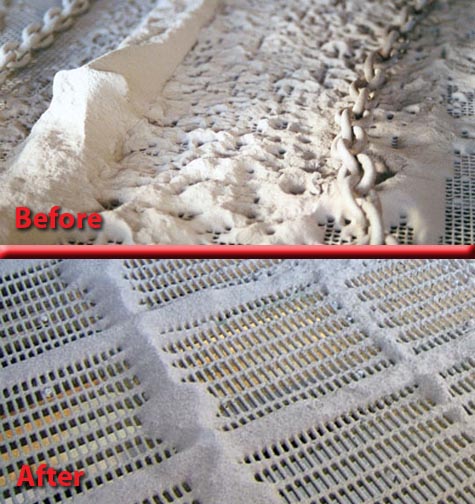

1) increase screen capacity and throughput, 2) eliminate blinding, pegging and clogging, 3) provide up to 3 times more wear life than the competition and 4) reduce annual screen media expenditures while increasing tons per hour. Its innovative offering includes Flex-Mat® 3 High-Performance, Self-Cleaning Screen Media in Tensioned and Modular versions; OptimumWire® Woven Wire and stainless steel wire and Double-Weave™ Woven Wire.

1) increase screen capacity and throughput, 2) eliminate blinding, pegging and clogging, 3) provide up to 3 times more wear life than the competition and 4) reduce annual screen media expenditures while increasing tons per hour. Its innovative offering includes Flex-Mat® 3 High-Performance, Self-Cleaning Screen Media in Tensioned and Modular versions; OptimumWire® Woven Wire and stainless steel wire and Double-Weave™ Woven Wire.

Flex-mat 3

Major Wire’s OptimumWire® is manufactured with High Carbon and High Manganese content, patented in diameters .250 inches (6.3 mm) and less.![]() Its high ductility, hardness and tensile strength make it less susceptible to breaking in high-impact conditions and with highly abrasive materials, so it lasts up to 40% longer and minimizes labor, maintenance and lost production costs.

Its high ductility, hardness and tensile strength make it less susceptible to breaking in high-impact conditions and with highly abrasive materials, so it lasts up to 40% longer and minimizes labor, maintenance and lost production costs.

Polydeck Screen Corporation is the pioneer inventor, innovator, and provider of the worlds most dependable modular synthetic screen solutions.  All of their screen panels are manufactured using an injection molding process. This process means that they are not glued or bolted. Their panels have versatile fastening systems. They also have superior resistance to blinding and pegging, and reduce noise by as much as 50% over steel. Polydeck modular screen panels are easier to install handle and remove than other traditional screens.

All of their screen panels are manufactured using an injection molding process. This process means that they are not glued or bolted. Their panels have versatile fastening systems. They also have superior resistance to blinding and pegging, and reduce noise by as much as 50% over steel. Polydeck modular screen panels are easier to install handle and remove than other traditional screens.

Blinding occurs when moist dust or fine material builds up around screen openings. This creates a situation where the opening is covered or “blinded” this drops efficiency dramatically. Industry solutions have included washing or slap chains ball cages or heated decks but they are usually temporary fixes and always come at a cost.

Polydeck addressed this issue by creating innovative screen panels called “VR”. Instead of inflexible openings Polydecks VR panel has rows of diamond shaped openings attached in strategic intervals that this allows vibrating action within the openings that prevents buildup.

For more information on VR technology please see Polydeck’s brochure on Blinding.

Blinding solutions from Polydeck

For solutions to other problems plaguing the aggregate industry download more information from Polydeck.

Polydeck ‘s new extreme duty screens. Armadex is a top deck extreme duty screening solution created for the most extreme scalping applications. Binary Injection Molding (BIM) technology Polydeck’s proprietary manufacturing process produces over ten times the pressure normally used to manufacture other compression molded rubber. Polydecks use of premium blend gum rubbers and high-strength low-alloy (HSLA) steel plate backing results in a product with extraordinary strength and uniformity in structure and composition. As a result the screens have a longer wear with the lowest dollars per ton investment. As an added benefit the BIM process allows customization options traditionally not available to other bolt screen products.

Polydeck ‘s new extreme duty screens. Armadex is a top deck extreme duty screening solution created for the most extreme scalping applications. Binary Injection Molding (BIM) technology Polydeck’s proprietary manufacturing process produces over ten times the pressure normally used to manufacture other compression molded rubber. Polydecks use of premium blend gum rubbers and high-strength low-alloy (HSLA) steel plate backing results in a product with extraordinary strength and uniformity in structure and composition. As a result the screens have a longer wear with the lowest dollars per ton investment. As an added benefit the BIM process allows customization options traditionally not available to other bolt screen products.

Bolt Armadex screen sections to your existing deck form or install with Polydecks versatile PipeTop II™ frame. All Armadex™ panels are backed by renowned Polydeck service and support, and provide the longest wear life and shortest lead time . . GUARANTEED!

Polydeck’s Screen Options Sheet

Polydeck Screen Options

Square The common style; 250 different size designs

Slotted: Used for draining liquid or elongated material is acceptable; 150 different opening sizes are available

VR: Zigzag design to minimize trapped material; 135 different opening sizes and configurations

SVR: A good alternative for working with elongated materials; 50 different configurations and openings offered

Round Very effective in primary scalping operations; they offer openings from 60mm to 230mm and in 13 different sizes

Solid Best suited for heavy wear; this is typically used at the feed or discharge ends of the screen

Continuous Slot: Six different slot widths from 0.5 mm to 2.5 mm

Dams: One-piece panel with 1, 2, or 3 inch dams

Restricted Flow panels: Control material flow rates and intensify dewatering and washing effects

Skid Bars: Used to keep oversized material off the screen panel surface

Deflectors: Used to redirect material towards the middle of the panel

Static Screen Panel: Ridged to intensify dewatering; opening sizes from 0.25 mm x 9 mm to 1.2mm x 14.5 mm