slurry pumps & Hose

By combining our world-class engineering solutions, process knowledge and global service center network, Weir Minerals supplies individual products, designs solutions and installations of entire plants. Through our local service engineers, our teams are able to facilitate training sessions or provide rapid response – whatever your needs, Weir Minerals is there to support you.

Industry selections include:

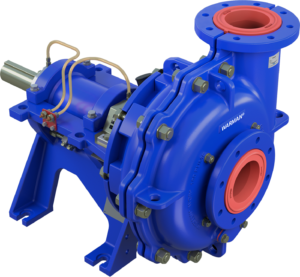

- Our heavy-duty pumps including the Warman AH and WBH pump range are designed to perform continuous pumping of abrasive slurries in many applications.

- Our line of vertical pumps is acknowledged in all industries for dependability, economical start-up cost, and low maintenance.

- Warman SHW and SJG submersible slurry pumps provide solutions for plant sumps and tailings removal.

- The WGR slurry pump is designed for slurry handling duties in sand and aggregate applications. it features fully replaceable liners that are manufactured from abrasion-resistant Linatex premium rubber.

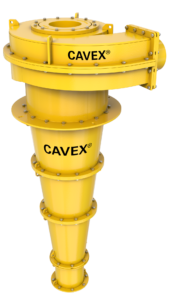

- The innovative Cavex Hydrocyclone design provides excellent classification efficiency and hydraulic capacity.

- Isogate slurry valves are the proven choice for highly abrasive slurry applications. They offer unique designs developed for ease of maintenance and low overall ownership costs.

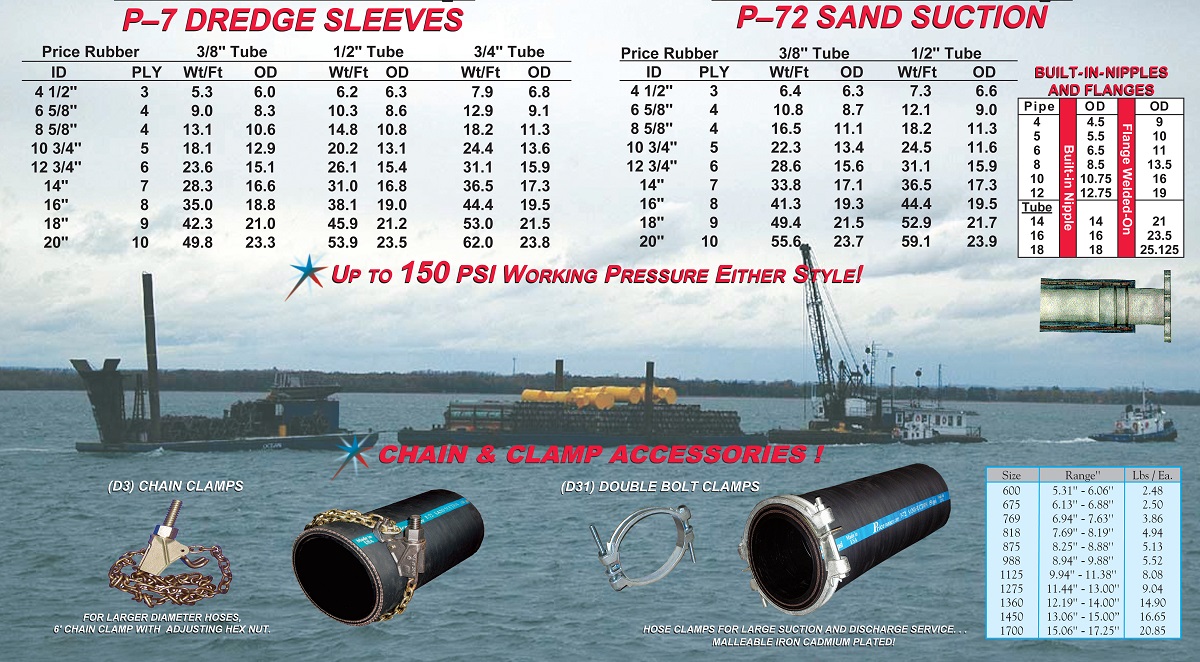

Linatex Hoses and Expansion Joints

- Our Linatex Range of Moulded Products is available for chutes and launders.

- Linatex premium rubber products are expertly manufactured to deliver outstanding wear performance. Available for highly abrasive wet environments and dry abrasion applications.

- Capabilities include Linatex hand-laid cold bond lining services and hot vulcanized rubber lining. Standard and custom-lined fabrications include pipe, chutes, elbows, and transition pieces.

- Linatex premium rubber dual-durometer belt scrapers efficiently clean conveyor belting at the head pully in both secondary and return cleaning positions. Linard skirt board helps keeps spillage and dust contained and offers long life over traditional skirting.

- Our wear resistant mill linings are custom designed to optimize mill performance and productivity while reducing power consumption, maintenance downtime, and reprocessing costs.

- Package wash plants and custom system capability to fit your specific need, from changing the design spec of your plant to building a new plant from scratch, our engineers are here to assist you.